Databricks is once again expanding its data lakehouse empire. The company just announced the Databricks Lakehouse for Manufacturing, an enterprise lakehouse platform tailored for the specific challenges of manufacturers.

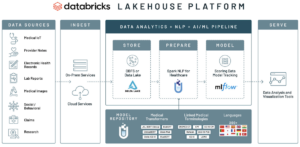

A data lakehouse is an architecture that combines features of both data lakes and data warehouses, resulting in a unified platform for data storage, processing, analytics, and AI. Modern manufacturing environments require multiple tools and systems that can make data sharing and collaboration a challenge to scale, Databricks says. According to a McKinsey study, 70% of data projects in the manufacturing industry stall at the proof-of-concept phase. Databricks says its Lakehouse for Manufacturing breaks down data silos for easier data access and goes beyond the limitations of traditional data warehouses because it offers integrated AI capabilities and pre-built solutions. The company asserts the platform’s data governance and sharing features are built-in to deliver real-time insights for agile manufacturing and logistics.

AI powers several new features in the Databricks Lakehouse for manufacturing. Customers can create digital twins with data derived from sensors for real-time monitoring and modeling of systems which can help optimize processes, risk assessments, condition monitoring, and design. Predictive maintenance capabilities allow manufacturers to ingest IoT data from field devices to perform complex time-series processing and KPI reporting. Supply chain optimization features like part-level forecasting can enable demand forecasting at the part level instead of the aggregate level. The platform also enables the development and implementation of computer vision applications to automate manufacturing processes.

Another new capability in the lakehouse platform is the recently-announced Databricks Model Serving. This allows customers to run machine learning models directly from the Databricks platform. The company says that running production ML inference workloads directly from the lakehouse allows for closer integration to the data and model lineage, governance, and monitoring.

Databricks customers also have access to a partner ecosystem via Brickbuilder Solutions, which is a library of industry solutions built by Databricks partners. Examples of these include a predictive supply risk management solution by data science solutions firm Tredence and an automated production quality control solution from DataSentics, an Atos-owned AI and ML specialist.

Consulting firm Deloitte is also a partner with its Smart Migration Factory Offering for automated monthly management reporting: “Using the Lakehouse for Manufacturing, a business can utilize all data sources in their value chain so that the power of predictive AI and ML insights can be realized to identify inefficiencies in production processes, improve productivity, enhance quality control, and reduce supply chain costs. This data-driven manufacturing is where we see the industry going as companies seek to accelerate their Smart Factory transformations,” said Anthony Abbattista, principal and smart factory analytics offering leader at Deloitte.

Databricks Lakehouse for Manufacturing is the latest in a series of industry-specific lakehouses from Databricks, including those for healthcare and life sciences, media and entertainment, and financial services. The Databricks Lakehouse platform is built on top of the open source distributed computing system Apache Spark, as well as Delta Lake, a transactional data management and storage layer, both of which were created by Databricks founders. With the lakehouse architecture, customers can store and process complex streams of both structured and semi-structured data in large volumes. The platform also provides an integrated workspace for collaboration between data scientists, engineers, and analysts, as it supports popular programming languages like Python, R, and SQL.

Databricks asserts its Lakehouse for Manufacturing has thus far been adopted by DuPont, Honeywell, Rolls-Royce, Shell, and Tata Steel.

“With rising costs, plateauing industrial productivity, and talent gaps, manufacturing companies are facing unprecedented operational challenges. At the same time, autonomy, connectivity, and electrification are shaping an entirely new approach of software-defined products that require a transformation of the business and operating model to be competitive and innovative. In the next 5 years, the companies that outperform in this industry will be the ones that not only manage data but effectively operationalize the value from data, analytics, and AI at scale,” said Shiv Trisal, global industry leader for manufacturing at Databricks. “We are very excited to launch tailored accelerators that target the industry’s biggest pain points and collaborate with leading partners to introduce Lakehouse for Manufacturing, enabling data teams to boost industrial productivity, gain nth-tier supply chain visibility and deliver smarter products and services at an accelerated pace.”

Related Items:

Databricks Launches Lakehouse for Healthcare and Life Sciences

Databricks Brings ML Serving into the Lakehouse

Databricks Bucks the Herd with Dolly, a Slim New LLM You Can Train Yourself

The post New Databricks Lakehouse for Manufacturing Aims to Ease Industry Challenges appeared first on Datanami.

0 Commentaires